Case 06 Flexible Extension

Introduction

In this course, we will lead students to explore the operating mechanism of the servo and learn how to accurately control the height of the XGO Rider robot through programming. Students will master programming to adjust the height of the XGO Rider through hands-on practice, so that the XGO Rider can be more interesting and agile.

Teaching Objectives

Understand the principle of the servo.

Learn the programming instructions for adjusting the height of the XGO Rider.

Teaching Preparation

Before starting teaching, please make sure you have prepared the following necessary materials:

| micro:bit V2 |

|---|---|

| XGO-Rider |

| USB Cable |

| PC |

These materials will provide you with a complete experience and ensure that you can smoothly carry out subsequent operations and learning. If you are ready for the above, we can proceed to the next step.

After turning on the XGO Rider, in order to keep the fuselage balanced, it needs to move back and forth slightly. Please do not place the XGO Rider on the edge of the table or in a dangerous place to avoid damage.

After turning on the XGO Rider, in order to keep the fuselage balanced, it needs to move back and forth slightly. Please do not place the XGO Rider on the edge of the table or in a dangerous place to avoid damage.

Teaching process

Course introduction

In this course, we will study in depth the working principle of the servo and explore how to program the height of the XGO Rider. You will learn to adjust the height of the robot through practice to adapt to various task requirements. This will deepen your understanding of robot kinematics and improve your programming ability to make the XGO Rider movements smoother and more natural.

Exploration Activities

What is the movement principle of XGO Rider's height change?

How to adjust XGO Rider's height through programming?

What is the range of XGO Rider's height change?

Start Programming

Add XGO Rider Software Library

1. Go to "makecode.microbit.org" and click New Project.

2. Enter the project name in the pop-up window and click Create.

3. Click Extension in the code drawer, enter XGO Rider in the search box on the pop-up interface and click the search icon. Click it after the XGO Rider software library is displayed.

Sample Program

Reference Program Link: https://makecode.microbit.org/_f087mb7eWCzw

Because XGO Rider has forward and backward movement in the performance mode, please place XGO Rider on a spacious flat ground.

Because XGO Rider has forward and backward movement in the performance mode, please place XGO Rider on a spacious flat ground.

Download Program

1. Use a USB cable to connect PC and micro:bit V2.

2. After the connection is successful, a drive letter named MICROBIT will be recognized on the computer.

3. Click  in the lower left corner and select Connect Device.

in the lower left corner and select Connect Device.

4. Click 。

。

5. Click 。

。

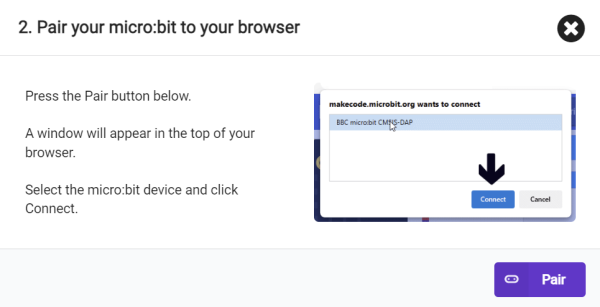

6. Select BBC micro:bit CMSIS-DAP in the pop-up window, and then select Connect. Now our micro:bit has been successfully connected.

7. Click Download Program.

Teamwork and Presentation

Students are divided into groups to jointly understand the motion principle and program the control of XGO Rider.

Students are encouraged to cooperate, communicate and share experiences with each other.

Each group has the opportunity to show their programmed XGO Rider to other groups and demonstrate.

Expected results:

Summary and reflection

Review the course content and remind students what knowledge and skills they have mastered?

Guide students to discuss the problems and difficulties they encountered during the production process and how to solve these problems.

Guide students to think and discuss whether there are other mechanical motion structures for bipedal robots.

Extended knowledge

XGO Rider is equipped with a 4.5KG.CM all-metal magnetic encoding bus serial servo. This high-performance servo motor is widely used in robots, automation equipment and precision control systems.

Brief description of working principle:

Motor drive: A small DC motor receives a control signal and generates a rotational torque.

Position feedback: The magnetic encoder provides accurate position information.

Control algorithm: The built-in microcontroller runs the algorithm to ensure precise control.

Communication capability: Interact with the control system through bus and serial port.

Power management: Internal circuit ensures stable power supply.

Its core features are as follows:

- High torque: With 4.5KG.CM torque, it can provide strong rotational force.

- Durability: All-metal construction enhances durability and stability.

- Precise feedback: The magnetic encoder provides accurate position feedback, which is better than traditional potentiometer encoders.

- Efficient communication: Supports bus protocol and simplifies system wiring.

- Serial port interface: Data transmission with the control unit through serial communication.

This servo has become the first choice for precision control applications due to its high precision and high reliability.