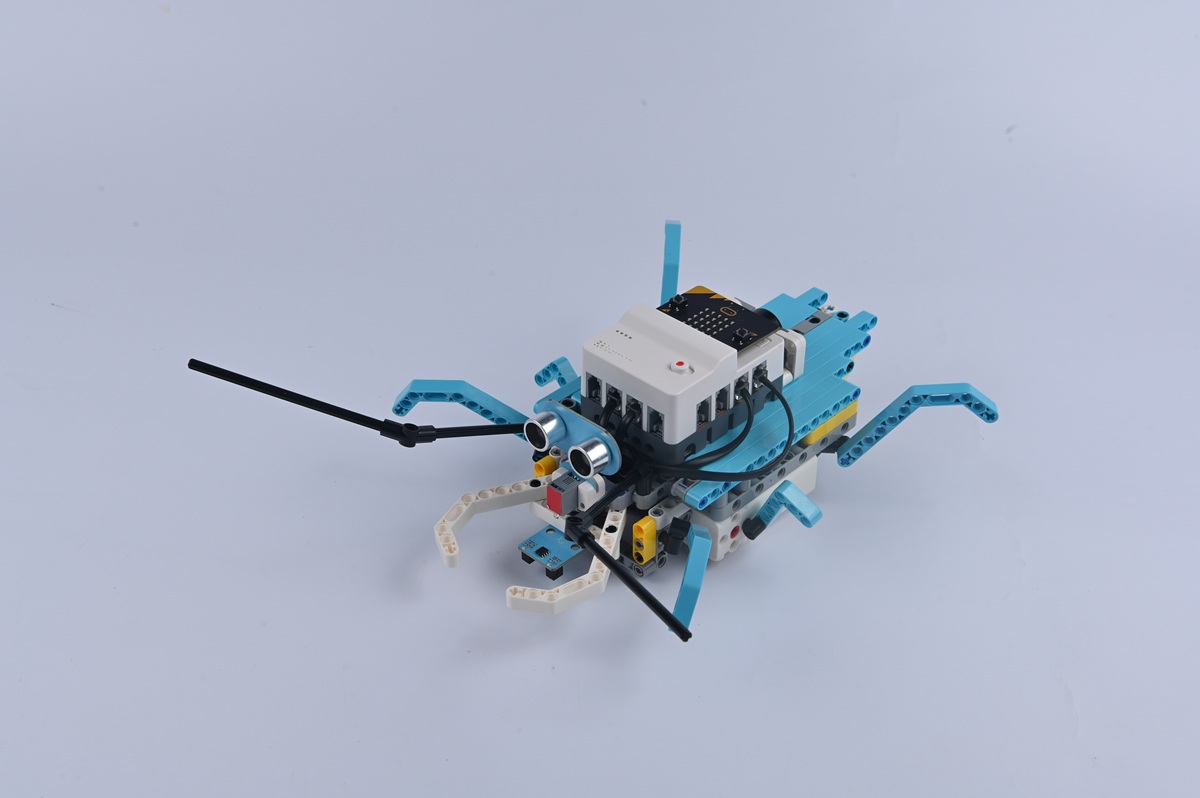

Case 16: Voice-Controlled Beetle Robot

Case Introduction

Build a voice-controlled beetle robot and control its functions via voice commands.

Teaching Preparation

| Name | Illustration |

|---|---|

| Nezha Pro AI Mechanical Power Kit |  |

Teaching Objectives

- Complete the assembly of the voice-controlled beetle robot, master the assembly and connection methods of the line-tracking sensor, ultrasonic sensor, voice recognition sensor, and motors, and realize the collaborative operation of three core functions: "voice control", "obstacle avoidance mode", and "line-tracking mode".

- Understand the functional division of different sensors (voice recognition sensor receives commands, ultrasonic sensor detects obstacles, line-tracking sensor recognizes paths), and learn to program "voice-controlled mode switching" (e.g., switching between obstacle avoidance/line-tracking via voice commands) and motor action control under each mode (e.g., turning when avoiding obstacles, moving along the path in line-tracking mode).

- During the process of debugging sensor sensitivity, mode switching logic, and motor action coordination, cultivate hands-on practical ability, multi-module collaborative thinking, and problem-solving ability (e.g., solving issues such as line-tracking deviation, delayed obstacle avoidance, and stuck mode switching).

- Stimulate interest in "multi-sensor fusion + biomimetic robots", perceive the technical charm of "intelligent control + environmental perception", and establish the cognition that "technology simulates biological perception and movement".

Story Introduction

With all parts in place, Aji became serious: "The final step is to deliver the repair chip into the server. The space inside is too small—only 'Xiao Qiang (Little Roach)' can get in." A small robot resembling a cockroach crawled out of the toolbox. "It can crawl through gaps and turn by recognizing voice commands," Aji demonstrated. "Say 'move forward 5 centimeters', and it will move precisely. Be careful—the internal circuits of the server are like a maze." When the children successfully directed Xiao Qiang to insert the chip into the interface, the lights of the entire village suddenly turned on—all robots had returned to normal. The village chief and villagers cheered and swarmed in. Aji smiled and said to the children: "Look, you not only repaired the robots but also learned to create miracles with technology. This is the real magic of science and innovation!"

Learning Exploration

- What core commands does the voice recognition sensor need to receive? (e.g., "beetle forward", "switch to obstacle avoidance mode", "switch to line-tracking mode") During programming, how to ensure that voice commands can accurately trigger the switch between "voice control" and "automatic modes (obstacle avoidance/line-tracking)"?

- How does the ultrasonic sensor work in obstacle avoidance mode? (e.g., when the detected distance to an obstacle ahead is less than a certain value, the motor drives the beetle to turn) If the ultrasonic sensor detects inaccurately, what problems may occur to the beetle (e.g., colliding with obstacles, false triggering of turns)?

- How does the line-tracking sensor recognize paths (e.g., recognizing black guide lines) in line-tracking mode? How does adjusting the sensor's height or angle affect the line-tracking effect? (e.g., too high a height leads to failure in recognizing the path, inclined angle leads to deviation from the path)

- Try adding voice commands in "obstacle avoidance mode" (e.g., "pause obstacle avoidance, move forward 5 centimeters"). During programming, how to handle the priority between "automatic mode" and "manual voice commands"? If there is a conflict (e.g., obstacle avoidance requires turning while the voice command requires moving forward), how to optimize the logic?

- Compare the motor actions of the beetle in "manual voice control", "obstacle avoidance mode", and "line-tracking mode". What are the differences in motor speed and steering adjustments? (e.g., one side of the motor decelerates when turning in obstacle avoidance mode, and the speed of both side motors is fine-tuned to stay on the path in line-tracking mode)