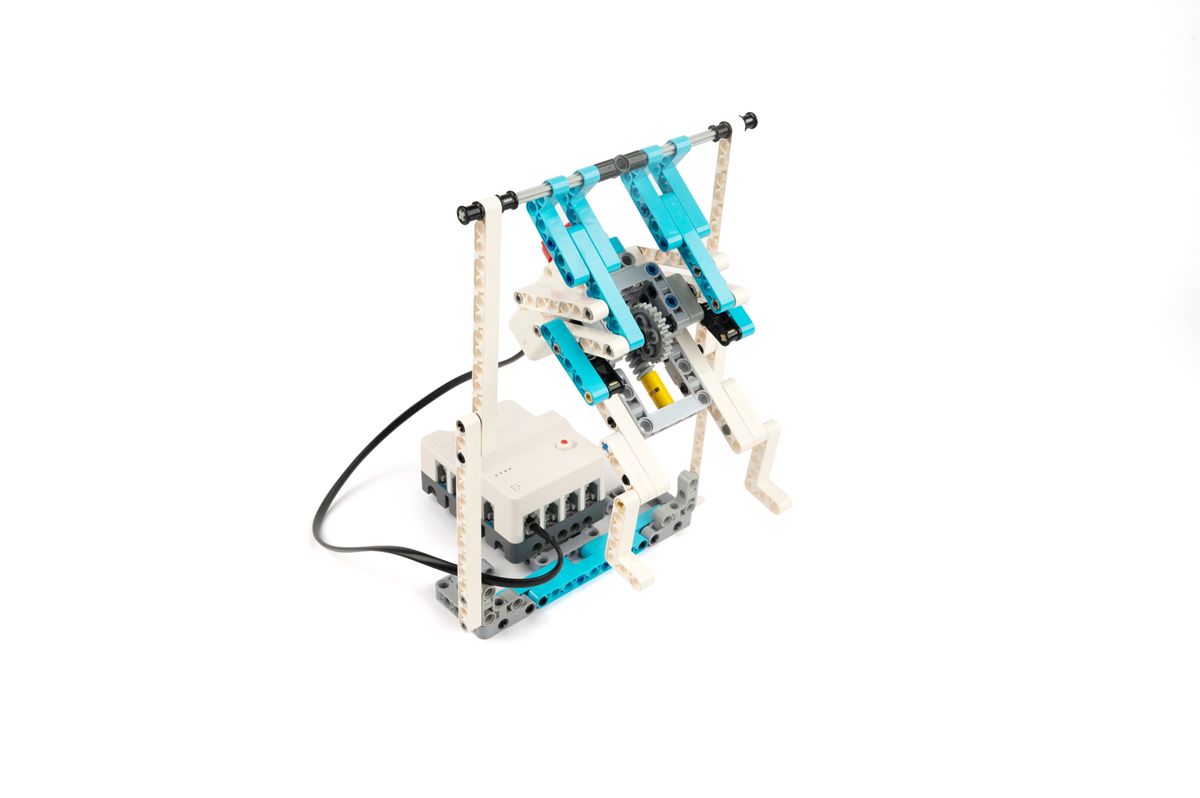

Design a pull-up robot that simulates the pull-up action.

Understand the characteristics and construction methods of worm gears

Inspire interest in engineering and robotics.

Welcome children to join our wonderful STEAM journey! Today, we will explore how to make a pull-up robot without programming. In this project, we will learn how to control the movement of the robot through simple mechanical transmission. You don't need complex programming knowledge, just assemble and adjust it by hand, and you can create a pull-up robot. Let's start this exciting STEAM learning journey together and stimulate your creativity and problem-solving skills!